KOKUSAI ELECTRIC’s Technology

The Group operates businesses that revolve around the deposition process that affects the performance of semiconductor devices and the treatment (film property improvement) process — two of the many processes that go into manufacturing semiconductors. These processes can be divided into two types: single wafer and batch processing. Single wafer processing refers to deposition of one wafer at a time, while batch processing is the deposition of several dozen wafers at once, and thus more productive. Our Group’s batch deposition and single wafer treatment equipment have earned high acclaim from semiconductor device manufacturers worldwide and boast among the highest share in the world.

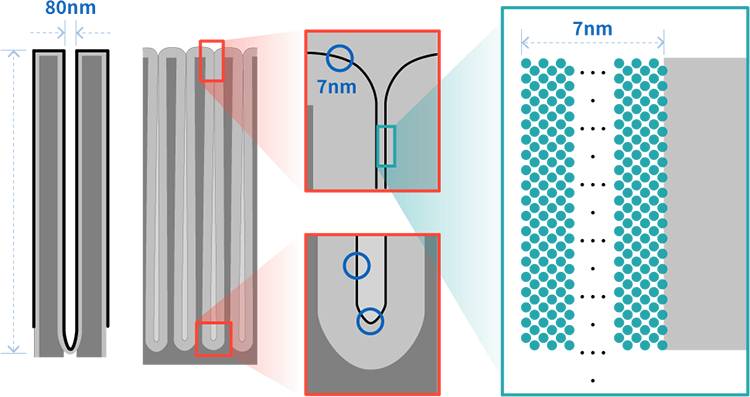

With the shift in demand from traditional consumer devices like computers and smartphones to high-growth industries such as data centers, next-generation mobile communication system, and AI*1, the semiconductor device market is experiencing an expansion. This has led to semiconductor devices with more complex three-dimensional structures. In response to this evolution of semiconductor devices, the Group has met the needs of worldwide semiconductor device manufacturers by developing and enhancing nanoscale deposition technology that can be used on wafers with a large number of deep, narrow, high-aspect-ratio*2 trenches and holes, and treatment technology that improves film properties by applying plasma and heat.

This technology is not something developed overnight, but the result of combining a wide range of fields — from thermofluid dynamics, mechanical engineering, control engineering, and electrical and electronic engineering to materials engineering, physical engineering, and plasma engineering. Never satisfied with the status quo, we produce innovations to meet the needs of customers by continuously making improvements to and merging the technologies in each of these fields.

Batch ALD Technology

ALD (Atomic Layer Deposition)*3 technology is an extremely difficult technology capable of forming high-quality thin film with outstanding step coverage*4. As semiconductor devices evolve, needs for the technology grows. Since ALD technology requires the cyclical supply of multiple gases, deposition is time-consuming, and thus not very productive. Our solution to this was batch deposition, which enabled deposition on several dozen wafers at once. The Group’s batch ALD technology combines ALD technology with batch deposition technology, balancing highly difficult thin film formation with high productivity. This enables deposition with high productivity and outstanding step coverage, even on wafers with a high number of high-aspect-ratio trenches and holes, thus providing the most logical solution to meet the needs of evolving semiconductors and expand their applications.

Treatment (Film Property Improvement) Technology

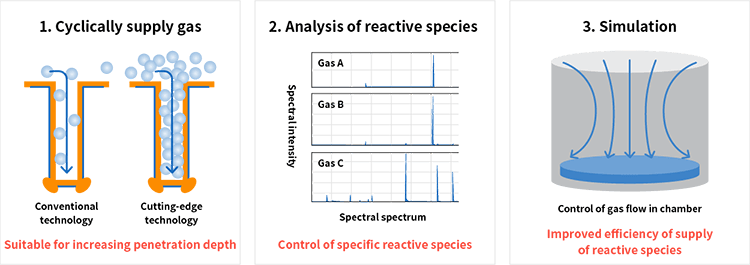

Treatment (Film Property Improvement) technology improves film properties by removing impurities from the film and stabilizing particles with plasma and heat after deposition. As semiconductor devices become more minute and complex, the demand for deposition in low-temperature environments has grown. Demand has also increased for treatment technology as a solution to improve film properties in low-temperature environments.

The Group focuses effort on developing treatment technology with new techniques. We have developed treatment techniques to increase the quality of existing thin film to ensure semiconductor devices can perform satisfactorily even under harsh conditions. For example, thanks to developing a process to supply large amounts of reactive species, we were able to provide a treatment method with outstanding step coverage even in 3D-NAND with deep holes of over 200 layers and it was adopted by a major memory manufacturer. We are monitoring and conducting simulations of reactive species types and phenomena with new ingredients, and analyzing reaction models, to develop more suitable treatment methods.

- *1

-

Artificial Intelligence

- *2

-

The aspect ratio of trenches and holes on a minutely fabricated semiconductor device.

- *3

-

We refer to a technique for thin-film deposition at an atomic layer level involving a process of cyclical supply of multiple gases as “ALD”.

- *4

-

The state of film coverage when depositing on a minutely uneven surface of a substrate.